Ultraviolet Air Disinfection Systems - Keep Liquid Storage Tanks Safe

UVC Germicidal Fixtures for Liquid Storage Tanks

If any part of your food or beverage manufacturing operation involves storing sweeteners like High Fructose Corn Syrup (HFCS), or water, to be used as ingredients in your products, then you are aware of the difficulty in keeping the headspace in your storage tanks and storage tank vents free from microorganisms. Particularly with the dark, moist, warm environment of nutritive liquid sweeteners, you face the obstacle of combating this ideal microorganism growth environment. Regular cleaning of your liquid storage tanks is certainly a great start to maintaining your liquid ingredients, including HFCS, as intended, but what about the headspace at the top of the tank? What happens when you drop out product and it is replaced by ambient air from inside (or outside) your facility? How do you ensure that that air is free from bacteria, viruses and mold spores? That’s where American Ultraviolet’s line of liquid sugar storage tank conditioners will help.

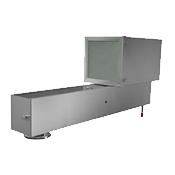

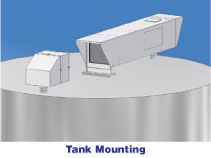

By passing all incoming air through a series of filters (up to 0.3micron, 99.7% efficient HEPA) and a properly sized UV disinfection chamber, for the required volume of air, you can achieve a >99.9% (3-log) reduction of airborne microorganisms. That means that everything that goes into your liquid storage tank remains usable. This can be done without placing any additional equipment inside your tanks by using our LTC, BT and SC series Liquid Tank conditioners.

By passing all incoming air through a series of filters (up to 0.3micron, 99.7% efficient HEPA) and a properly sized UV disinfection chamber, for the required volume of air, you can achieve a >99.9% (3-log) reduction of airborne microorganisms. That means that everything that goes into your liquid storage tank remains usable. This can be done without placing any additional equipment inside your tanks by using our LTC, BT and SC series Liquid Tank conditioners.

For potable liquid sugar tanks, an internally mounted setup of one or more UVC lamps can provide the needed headspace and surface disinfection needed to keep your tank clean indefinitely. Our TTG series units, featuring lamp status indication located outside the tank, is the perfect solution.

For potable liquid sugar tanks, an internally mounted setup of one or more UVC lamps can provide the needed headspace and surface disinfection needed to keep your tank clean indefinitely. Our TTG series units, featuring lamp status indication located outside the tank, is the perfect solution.

In-line Disinfection Equipment

Do you have a requirement for in-line UVC treatment of water or liquid sweeteners? American Ultraviolet offers a full range of in-line systems for all liquid disinfection applications. In-line systems for water disinfection emit, at minimum, the EPA-required dose of 40,000 microwatts per square centimeter. Our water units fit applications from 0.5 gpm to millions of gallons per day. Please consult your authorized American Ultraviolet representative for proper sizing of in-line UV disinfection equipment.

Satisfied Customers

Following are a few of the many satisfied customers American Ultraviolet has helped with Ultraviolet Sterilization needs:

Following are a few of the many satisfied customers American Ultraviolet has helped with Ultraviolet Sterilization needs:

Coca-Cola Bottling

Pepsi Cola

M&M/Mars

Heinz Co.

Dr. Pepper/7-Up

Minute Maid

Hershey's

Sealtest Foods

Ralston Purina Co.

Molson Lion Brewery

Coca-Cola Bottling

Kraft

Dupont

Seagram & Sons

US Food & Drug Administration

Morningstar Foods

Anheuser-Busch

Guinness Brewing

Domino Sugar

National Starch

Mott's Juice

Caribe America Trading Company

UVC In-line Liquids

In-line liquid units can be used for everything from ingredient water in foods and beverages, to liquid sugar and other liquids not traditionally treatable with UVC water units, by using "thin-film" and "non-contact" technology.

In-line liquid units can be used for everything from ingredient water in foods and beverages, to liquid sugar and other liquids not traditionally treatable with UVC water units, by using "thin-film" and "non-contact" technology.

All food and beverage in-line liquid treatment applications are sized on a case-by-case basis, taking into account all of the specific requirements of the application.

UVC Water Treatment Units – Inline LS

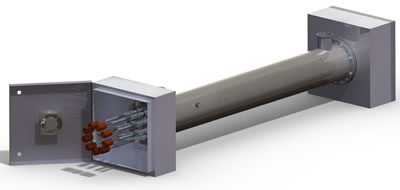

Many liquids that are almost opaque to UV can be treated inline by locating the UVC lamps very close together. In the following custom situation, 20 High Output UVC lamps were used in a 6" diameter vessel:

This tight grouping of lamps allows the UVC to effectively treat a sufficient amount of the liquid directly, without relying on the liquid's transmission, as is done with clean, clear water.

Cooling shrouds were created at the lamp ends (on either end of the vessel) to keep the UVC lamps within specified operating temperature. Typically, the liquid flowing through a vessel will act to cool the lamps sufficiently, but liquid sugar must stay hot to remain in liquid form, so external cooling of the lamps was required.

Lamp type, intensity and quantity were engineered to overcome the low transmission of the liquid and deliver the specified dosage.

Installation of a thin-film vessel to 100GPM of liquid sugar.

Electrical enclosure with an LED indicator light for each lamp.

Custom UVC Liquid Disinfection Solution

This custom food safety solution was designed to deal with a water source susceptible to contamination. A relatively high dosage of UVC through a high temperature liquid, with low UV transmission, was required. The result is a system capable of treating liquid with a UVT of 90% and temperature up to 190°F at a peak flow rate of 160GPM.

Cooling shrouds were created at the lamp ends (on either end of the vessel) to keep the Amalgam (high Intensity) UVC lamps within specified operating temperature.

Lamp type, intensity and quantity were engineered to overcome the low transmission of the liquid and deliver the specified dosage.

American Ultraviolet equipment is manufactured entirely in the USA.

Prolonged, direct exposure to UVC light can cause temporary skin redness and eye irritation. American Ultraviolet systems are designed with safety in mind and, when properly installed by a professional contractor, do not allow exposure to UV radiation and allow for safe operation and maintenance.