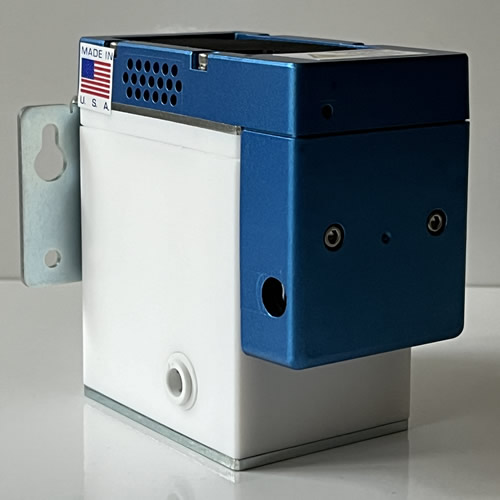

AQ Series

AQ Series UV-C water treatment units are designed for commercial and residential applications, and utilize the same technology necessary to safely and effectively purify water used in everything from soft drinks to shampoo. These economical fixtures are available in a wide range of flow rates, making them ideal for individual point-of use applications as well as whole-house installations. AQ Series Units are offered in flow rates from 2 to 50 gallons per minute, and all vessels are passivated stainless steel. These fixtures perform like our many other high-end industrial water treatment fixtures, however, we've eliminated some of the costly, sophisticated technology, and related accessories, that are simply unnecessary in residential applications, and deliver an extremely well-built series of water units for a very economical end-user price.

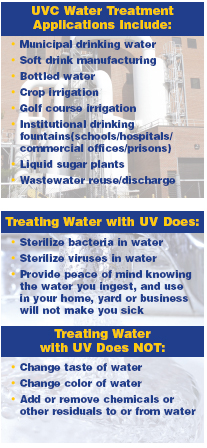

Water Treatment Benefits

- Reduces, and destroys, viruses and bacteria that may be resistant to chemical treatment

- Will not change color, odor, or taste of water

- Lamp change required only once per year

- Into standard household outlet - no electrician required

- Water passing through units receive a minimum UV-C dosage of 40,000µW

To learn more about UV-C water treatment, including technical specifications, and independent IES Test (AQ Series) results, please visit our technical library where you can download and print literature.

AQ Series water treatment units can be used to treat an individual faucet, multiple faucets, or installed to purify water throughout an entire home or business - any water source where it's important to provide bacteria and virus protection.

Crystal Clear UV-C Flow

Why do you need a UV water disinfection unit?

Properly applied UV-C water treatment systems inactivate microorganisms that may pass through traditional filtration systems used to treat municipal or well water sources, specifically parasites like Cryptosporidium and Giardia, which can cause very unpleasant digestive system issues. By installing properly sized UV-C systems as the final filtration step before water goes to use, you can keep these parasites out of your water supply. This can be especially useful in dealing with unknown water supplies like one may encounter at a campground or recreational area in refilling the potable water supply in a camper or RV.

What makes the FLOW series special?

- LED-based = no mercury lamps

- Flow sensor so it's only on when there's water flow = saves energy and prolongs system life

- Much smaller than comparable flow systems = easier to find a convenient install location

- Inlet/outlet are interchangeable = even easier to install

- Quick-connect push-in fitting make plumbing easy = super easy to install

What are the differences between a traditional UV-C water unit and a UV-C LED water unit?

- Traditional systems use mercury-vapor lamps, which are made from a quartz glass envelope and contain mercury to create the germicidal energy to inactivate viruses, bacteria, and other unwanted microbes. In larger scope applications, this is still the most effective technology, but also creates a disposal issue with used bulbs which still contain mercury. LEDs contain no mercury, nor glass, thus have none of these drawbacks.

- Traditional UV-C bulbs lose effective lifetime by frequent on/off cycles, meaning they should be left on all the time to achieve maximum useful lifetime. LEDs can be turned off and on as dictated by water flow to only function when needed. This extends useful UV-C LED lifetime and reduces power consumption.

In many applications, LED technology can be significantly more expensive than traditional UV-C systems. In the case of lower flow rates, such as POU (Point of Use) systems around 2 gallons per minute, this is no longer the case. UV-C LED water treatment, like the Crystal Clear UV-FLOW from American Ultraviolet, can be had at a similar price point to traditional UV-C systems.

Specs

| Model | FLOW-2 |

| Max Flow Rate | 2 GPM (8 LPM) |

| Operating pressure | 10-100 psi |

| Max Water Temp | 104° F (40° C) |

| Electrical | 80-240VAC / 50-60Hz |

| UV-C Dose | > 20mJ/cm² |

| Inlet/outlet | Push-fit ¼" Quick Connect |

| Unit Dimensions | 3.5" x 2" x 3.65" |

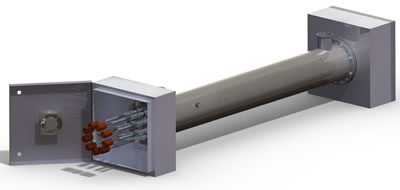

UV-C Water Treatment Units – Inline LS

Many liquids that are almost opaque to UV-C can be treated inline by locating the UV-C lamps very close together. In the following custom situation, 20 High Output UV-C lamps were used in a 6" diameter vessel:

This tight grouping of lamps allows the UV-C to effectively treat a sufficient amount of the liquid directly, without relying on the liquid's transmission, as is done with clean, clear water.

Cooling shrouds were created at the lamp ends (on either end of the vessel) to keep the UV-C lamps within specified operating temperature. Typically, the liquid flowing through a vessel will act to cool the lamps sufficiently, but liquid sugar must stay hot to remain in liquid form, so external cooling of the lamps was required.

Lamp type, intensity and quantity were engineered to overcome the low transmission of the liquid and deliver the specified dosage.

Installation of a thin-film vessel to 100GPM of liquid sugar.

Electrical enclosure with an LED indicator light for each lamp.

Custom UV-C Liquid Disinfection Solution

This custom food safety solution was designed to deal with a water source susceptible to contamination. A relatively high dosage of UV-C through a high temperature liquid, with low UV-C transmission, was required. The result is a system capable of treating liquid with a UVT of 90% and temperature up to 190°F at a peak flow rate of 160GPM.

Cooling shrouds were created at the lamp ends (on either end of the vessel) to keep the Amalgam (high Intensity) UV-C lamps within specified operating temperature.

Lamp type, intensity and quantity were engineered to overcome the low transmission of the liquid and deliver the specified dosage.

UV-C Water Treatment for Healthcare

This custom 100 GPM water treatment solution featured a digital UV-C monitor with local display, and a 4-20mA signal out, to provide the building's monitoring system with the status of the UV-C water unit, along with the status of other systems (i.e. the building's HVAC), so that everything could be monitored from a central location.

Installation in a Surgical Center as a preventive measure against microbial contamination of incoming water supply.

American Ultraviolet equipment is manufactured entirely in the USA.

American Ultraviolet equipment is manufactured entirely in the USA.

Prolonged, direct exposure to UV-C light can cause temporary skin redness and eye irritation. American Ultraviolet systems are designed with safety in mind and, when properly installed by a professional contractor, do not allow exposure to UV-C irradiation and allow for safe operation and maintenance.