UVC Air Movers

CleanBox™ UVC + HEPA Air Mover

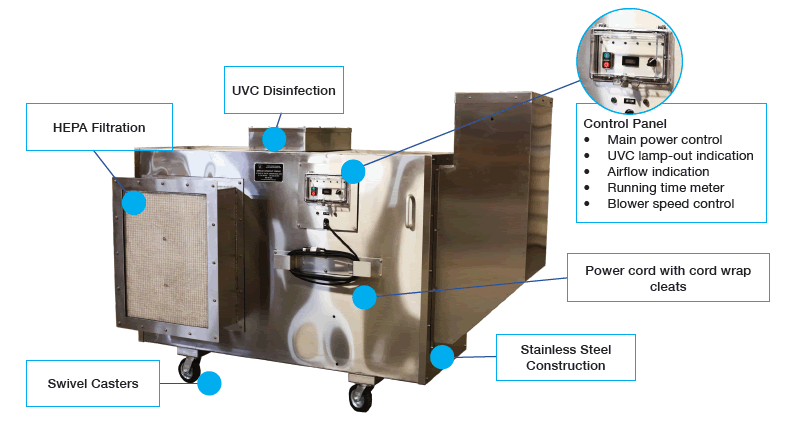

Designed to filter and disinfect the air in food processing areas, the CleanBox™ is portable so it can go where you want, when you want. Each CleanBox uses a combination of HEPA filtration and germicidal UVC light to reduce unwanted microorganisms from the air in your space. Offered in 4 sizes and handling up to 50,000 cubic feet with a single unit, there's a CleanBox for your application.

Designed to filter and disinfect the air in food processing areas, the CleanBox™ is portable so it can go where you want, when you want. Each CleanBox uses a combination of HEPA filtration and germicidal UVC light to reduce unwanted microorganisms from the air in your space. Offered in 4 sizes and handling up to 50,000 cubic feet with a single unit, there's a CleanBox for your application.

How Does It Work?

Air is drawn in via the blower located inside the unit and is drawn through:

Step 1:

Electrostatic prefilter - removes contaminants > 10-15 microns

Step 2:

HEPA filtration - removes contaminants > 0.3 microns

Step 3:

254nm germicidal UVC light chamber - sized to inactivate microorganisms

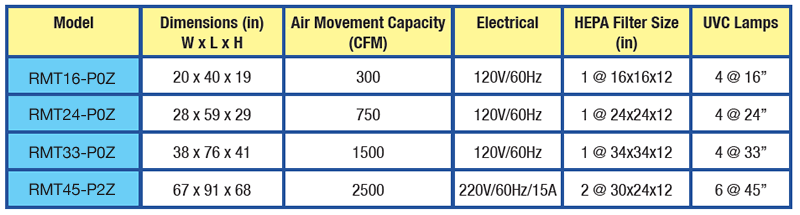

CleanBox™ Specifications Lamps

- High Output (800mA) UVC lamps

- LED indication of UVC lamp function

Filters

- Electrostatic prefilter

- 12" deep 0.3-micron HEPA filter(s)

Electrical

- See chart for electrical requirement per unit

- Power cord w/plug

- Illuminated push-button power on/off

Mechanical

- 304 stainless steel construction

- Swivel casters

CleanBox™ Options

- 316 stainless steel construction

- Galvanized steel construction

- Aluminum construction

- Alternate voltages

- Charcoal prefilter (replaces electrostatic prefilter)

- Bumper feet (replaces casters)

FRESH + Photocatalytic Oxidation

Photocatalytic Oxidation (PCO) is the process of generating free radicals (in our case, hydroxyl radicals OH molecules) by exposing a catalyst to an energy source. This process is extremely effective in destroying airborne contaminants like VOCs and other common microorganisms. PCO can also be used for the reduction of smoke, odors and ethylene gas in food production and food storage applications.

American Ultraviolet is partnering with Fresh Plus International to provide the fresh produce industry produce-centric solutions designed to improve food safety and maintain post-harvest quality of fresh produce. Our systems utilize shortwave UVC energy as the source to initiate the reaction, thus providing the added benefit of germicidal UV energy to the existing benefits provided by the creation of the free radicals

The outcome of extensive research, and subsequent trials, indicate a dramatic reduction in ethylene levels in fruit storage containers like walk-in refrigerators, box cars, and warehouses. This reduction in ethylene levels slows the aging or ripening process and extends the viable shelf / storage life for the products.

Features of Our Patented Design

FRESH+™ is recommended for use throughout the cold chain for conventional and organic produce. With a wide variety of models available, our expert engineers can recommend the right system for any space, from small coolers to large warehouses and production facilities.

Space-saving design allows our products to be mounted to the wall or ceiling. The FRESH+™ system is the only ethylene removal system on the market capable of handling "warehouse-size" space with a single unit, compared to other products that require 5-10 units to handle the job.

Models and Specifications

Fresh Plus International’s proprietary FRESH+™ brand of ethylene scrubbers utilize a powerful combination of UV disinfection and PCO to drastically reduce ethylene from coolers, processing and repack areas and in- transit, preventing ethylene damage such as:

Fresh Plus International’s proprietary FRESH+™ brand of ethylene scrubbers utilize a powerful combination of UV disinfection and PCO to drastically reduce ethylene from coolers, processing and repack areas and in- transit, preventing ethylene damage such as:

- Acceleration of senescence, ripening, softening, and discoloration (including but not limited to apples, pears, bananas, avocados, kiwi, apricots, peaches, nectarines, and tomatoes)

- Russet spotting (lettuce), yellowing and spotting (cabbage, broccoli and greens), bitterness (carrots and parsnips), sprouting (potatoes), and toughness (asparagus)

- Abscission (floral), epinasty and reduced production, (greenhouse)

Fresh Plus International’s FRESH+TM brand of equipment offers a wide variety of models to economically handle any size space from the smallest cooler to largest warehouse-sized space.

Our PCO systems can also be used for smoke and VOC reduction in populated spaces as a safe alternative to ozone generating systems. American Ultraviolet, in cooperation with Fresh Plus International offers solutions for all PCO applications from commercial / industrial to residential and personal use.

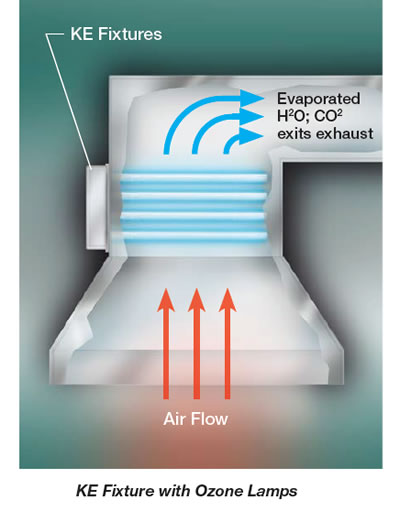

Kitchen Exhaust

American Ultraviolet Kitchen Exhaust (KE) hood germicidal fixtures are designed to reduce odor emissions and grease deposits commonly associated with kitchen exhaust hoods. They also contribute to a safer kitchen environment by lessening the dangers of grease fires.

KE Series fixtures are ideal solutions in diners, restaurants, fast food restaurants, and commercial kitchens (including those in hotels, casinos, convention centers, resorts, etc.); industrial kitchens that produce fish and meat meals; and other environments where grease and oil are used to bake or fry.

KE Series Fixtures feature UVC lamps, and ozone, and are easy-to-mount in two or four-lamp configurations – they may be mounted singly, or in parallel configurations in exhaust systems.

Food & Beverage KE Series Benefits

- Reduce risk of fires by minimizing grease deposits

- Reduce unpleasant odors

- Prolong equipment life by reducing grease build-up

- Eliminate need for extra cleaning of exhaust hood and ductwork

- Improve exhaust flow by keeping hood continuously clean

- Low operating and maintenance costs

- Easy-to-change lamps

To learn more about our UVC Air Movers, please visit our technical library where you can download and print literature.

Prolonged, direct exposure to UVC light can cause temporary skin redness and eye irritation. American Ultraviolet systems are designed with safety in mind and, when properly installed by a professional contractor, do not allow exposure to UV radiation and allow for safe operation and maintenance.