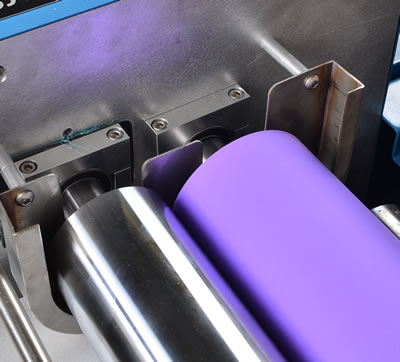

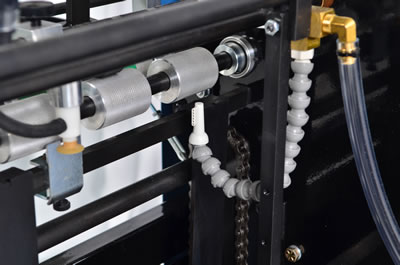

Remove four allen bolts on the two saddle brackets for easy change out of applicator roller for replacement, or change over to aqueous roller.

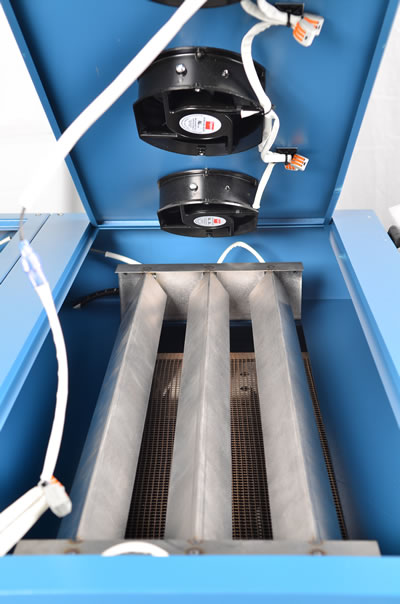

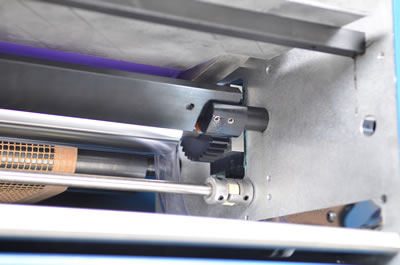

Easy access UV bulb chamber for simple maintenance and replacement of UV bulb.

Easy access to three adjustable output 1500 watt IR bulbs.

Delivery end of the UNI 25” roller coater UV Curing unit with light shielding and catch tray.

25” roller coater UV Curing unit with 22” X 28” deep pile feeder in line;

stackers are also available.

Doctor blade assembly is controlled by one handle on the operator side or the roller coater.

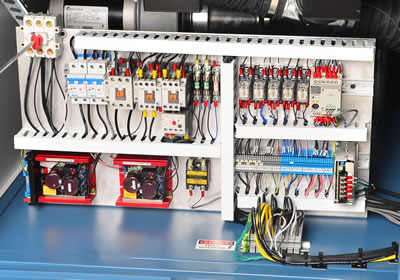

Easy-access electrical panel all assembled here in America at our California facility.

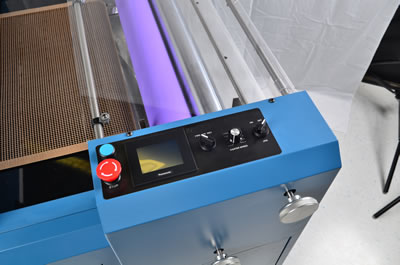

Simple control panel with touch screen PLC controls and digital error readouts.

22” X 28” feeder with auto and manual feed table raise and lower with adjustable run speed with a deep 18” pile height.

Eight belts for assured transfer from the feeder to the coater, and two adjustable pile sheet separator blowers.

Power for the feeder, and integrated controls for the feeder, are powered from the UV Roller Coater via quick disconnect cables.

A total of four adjustable sheet separators two from the side and two in the front of the 18” pile height capability.

Substrate height is controlled with an adjustable sensor for fine adjustments.